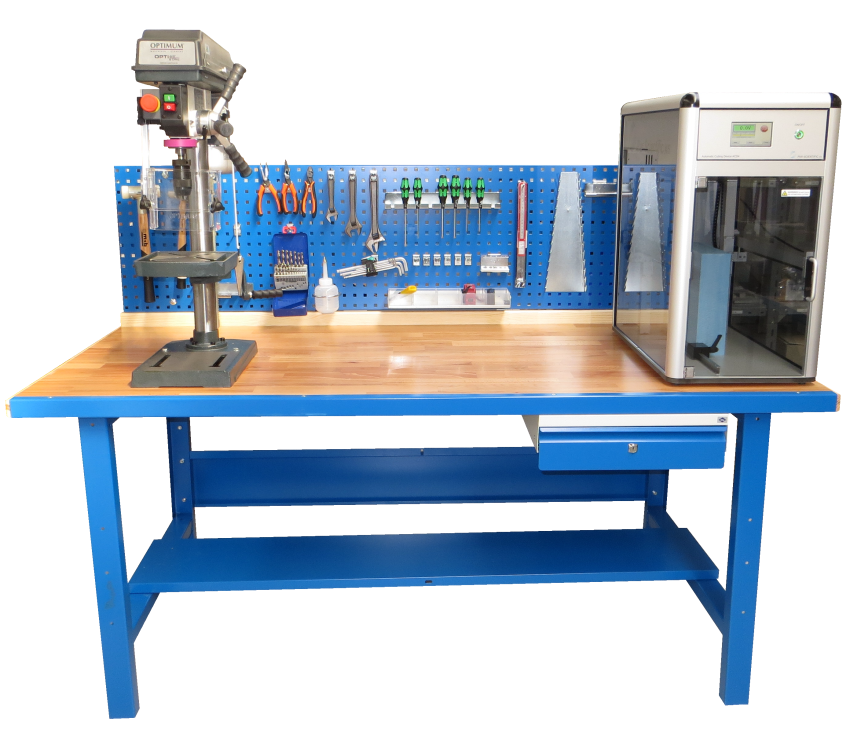

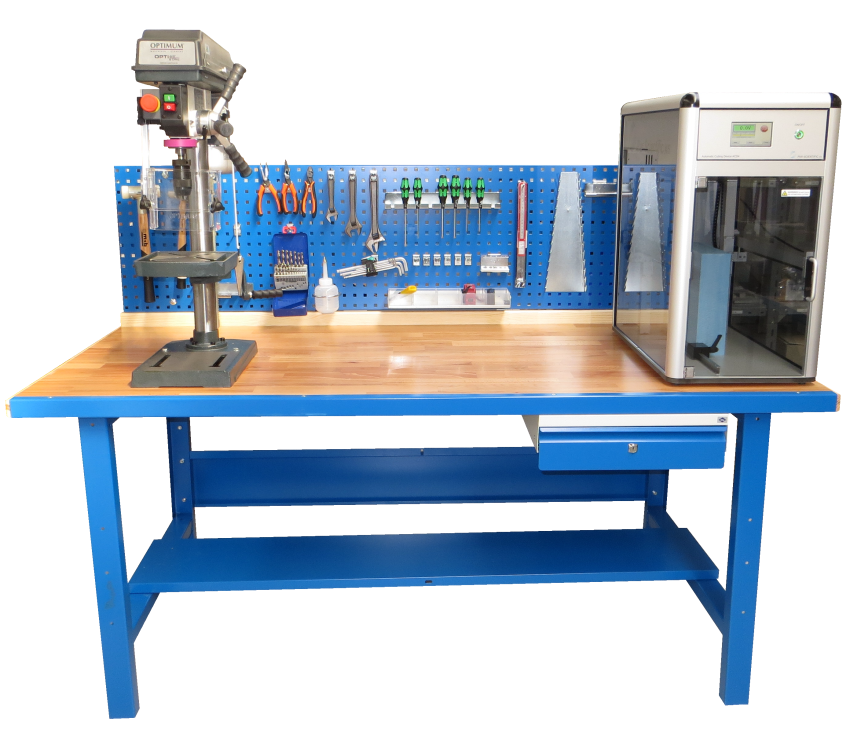

A turn-key mould room solution can be provided if desired. This mould room consists of two working areas:

- Workstation for melting and casting alloy. This area is equipped with exhaust system to remove any vapors that might arise during

melting of the alloy. The exhaust system is built for performance, yet low noise level (37dB(A) at 3 meters). It offers the ability to control the

exhaust volume on control outside the cabinet.

- Workstation for melting and casting alloy. This area is equipped with exhaust system to remove any vapors that might arise during

melting of the alloy. The exhaust system is built for performance, yet low noise level (37dB(A) at 3 meters). It offers the ability to control the

exhaust volume on control outside the cabinet.

It contains standard tools for this operation like cups and ladles for filling the styrofoam cavities, temperature measuring device, safety glasses, heat resistant gloves.

- Next to the melting pot, still inside the exhaust area, a water cooling plate is located for fast and efficient solidification of the casted alloy filters.

- An opening provides for easy access to the melting pot and the colling plate during operation. The exhaust system secures that no vapors are escaping to the outside working environment.

- Workstation for cutting the styrofoam including computer working area, cutting device and various tools and consumables for production of

alloy blocks. This includes screws for mounting on trays, electrical screwdriver and variety of tools.

- Workstation for cutting the styrofoam including computer working area, cutting device and various tools and consumables for production of

alloy blocks. This includes screws for mounting on trays, electrical screwdriver and variety of tools.

The mouldroom setup allows full customer freedom in choosing the setup / tools / consumables needed.

- Workstation for melting and casting alloy. This area is equipped with exhaust system to remove any vapors that might arise during

melting of the alloy. The exhaust system is built for performance, yet low noise level (37dB(A) at 3 meters). It offers the ability to control the

exhaust volume on control outside the cabinet.

- Workstation for melting and casting alloy. This area is equipped with exhaust system to remove any vapors that might arise during

melting of the alloy. The exhaust system is built for performance, yet low noise level (37dB(A) at 3 meters). It offers the ability to control the

exhaust volume on control outside the cabinet.It contains standard tools for this operation like cups and ladles for filling the styrofoam cavities, temperature measuring device, safety glasses, heat resistant gloves.

- Next to the melting pot, still inside the exhaust area, a water cooling plate is located for fast and efficient solidification of the casted alloy filters.

- An opening provides for easy access to the melting pot and the colling plate during operation. The exhaust system secures that no vapors are escaping to the outside working environment.

- Workstation for cutting the styrofoam including computer working area, cutting device and various tools and consumables for production of

alloy blocks. This includes screws for mounting on trays, electrical screwdriver and variety of tools.

- Workstation for cutting the styrofoam including computer working area, cutting device and various tools and consumables for production of

alloy blocks. This includes screws for mounting on trays, electrical screwdriver and variety of tools.The mouldroom setup allows full customer freedom in choosing the setup / tools / consumables needed.